Tanker - Oil Tanker

Concept Study - Handysize Oil- Chemical Tanker - P107 - 2010

Concept Study - Handysize Oil- Chemical Tanker

INEC made a concept study for a new handysize oil-chemical tanker design. The study is based upon the experiences from INEC's existing and successful design of a 19800 tdw oil- chemical tanker.

Motivation of the study

high demand for small sophisticated oil- chemical tanker in the maritime market

improvement of INEC's existing design of a handysize oil- chemical tanker based upon the experiences from the construction process and the feedback of the ships in service

new ideas and technical possibilities

new design tools such as 3D CAD

design of a modular platform with the possibility to realise individual owner demands

meet the today's and future class and environmental demands

Design targets of the study

Steel Structure

update of the steel structure according to the latest CSR revision (Common Structural Rules)

streamline the steel structure in the engine room to avoid edges and niches and optimise the foundation of the deck house above

improvement of the foundation of heavy components such as oil fired boiler, Diesel- generator sets, etc.

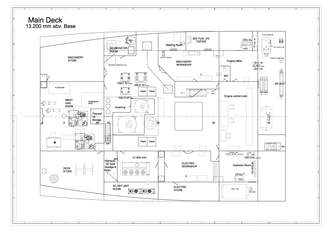

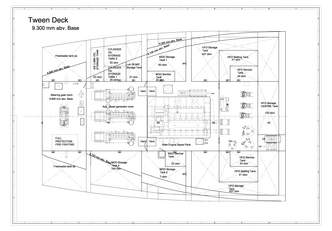

Engine Room Arrangement

reduction of the engine room volume to achieve a bigger cargo tank volume

reduction of noise level by separate rooms for

Diesel- generator sets

hydraulic power packs for cargo pumps

compressed air compressors

improvement of the engine room ventilation to avoid hot and cold spots

improved arrangement of components to achieve easy service and maintenance for an unmanned engine room

design of a modular engine room arrangement to meet different individual owner demands such as:

hydraulic or electric driven cargo pumps

two or four stroke main engine

shaft generator

nitrogen generator

etc.

Cargo Area

improved arrangement of cargo deck equipment such as

cargo pumps

cargo tank hatches

tank washing machines

fixed tank venting and drying ventilation

etc.

improved pipe rooting by using 3D design tools

Environmental aspects of the study

operation with regular or low sulphur HFO

two separated pairs of HFO storage, settling and service tanks

two cylinder oil storage tanks

Ballast water treatment to achieve the latest MARPOL regulations

high sophisticated vapour return system to avoid air pollution

Future Aspect of the study

totally diesel electric driven vessel with conventional shaft arrangement or POD drive

NOx reduction by using SCR (Selective Catalytic Reduction) or direct water injection systems

SOx reduction by using exhaust gas scrubber or low sulphur fuels

heat recovery

| Length over all | abt. 165 m | Deadweight all told | abt. 19800 t |

|---|---|---|---|

| Length between p. | abt. 155 m | Cargo tank capacity | abt. 23000 m3 |

| Breadth moulded | abt. 23 m | Main engine power | abt. 8000 kW |

| Depth to maindeck | abt. 13 m | Speed at design draught | abt. 15,5 kn |

| Draught moulded | abt. 9,5 m |